Our company has been built around a family identity based on expertise, human know-how and a very strong passion. We are regularly on the lookout for new talent for our workshops and methods office.

The complementary skills of our employees are our greatest strength. We share the same values and work together to develop synergies that enable us to rise to the greatest challenges.

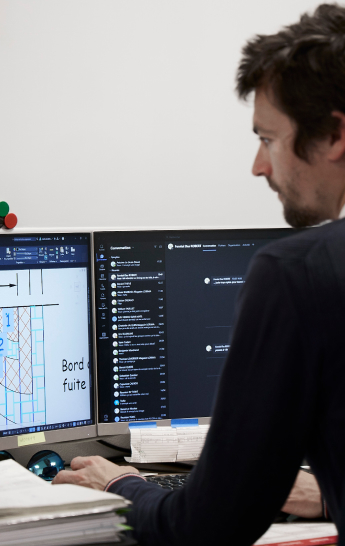

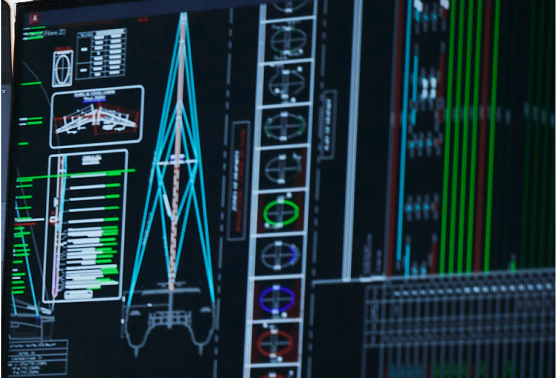

Lorima’s design office, made up of several engineers and draughtsmen, is responsible for the design, technical drawing and monitoring of the manufacture of our masts and spars.

Lorima’s design office can also call on external engineering companies to provide a more comprehensive design study.

To ensure uniform assembly and maximum precision of the parts we produce (carbon masts and spars), our lamination workshops then cure the carbon nparts in our autoclave.

“After studying nautical mechanics, I joined Lorima’s draping workshop. It’s a fulfilling job that requires patience and attention to detail. We work on beautiful projects in a pleasant atmosphere. Every mast I work on is unique, and I’m constantly learning. I’m proud to contribute to the construction of prestigious boats.”

After the assembly and composite quality control stagees (ultra-sound control carried out by an external firm), the parts pass through the assembly workshops.

These workshops are responsible for the most complex stages: sleeving, drilling, tapping and grafting of custom composite parts. (goosenecks, radar supports, mastheads, mastfoot, etc.).

“I joined Lorima’s assembly workshop after retraining. A rigorous handyman, I quickly found my place in the workshop. I’m proud to be able to help build masts for prestigious boats. For a sailing enthusiast like me, it’s a pleasure to watch the start of the races with my family, and to see the boats fitted with Lorima masts! The atmosphere in the assembly workshop is great, with several generations working together and helping each other out on a daily basis.

The paint/finish workshop, equipped with a 38-metre oven, carries out the sanding, painting and finishing of our masts.

The paints are heated to 60 degrees Celsius for an impeccably uniform finish and maximum durability.

“After a career in catering, I learnt the painter’s trade when I joined Lorima.Painting is an important stage in the manufacturing process of the parts, which highlights all the work done upstream. I love seeing the parts leave our workshop with an impeccable finish. It demands rigour and precision. What do I like best about Lorima? Our team is very close-knit and we work together in a great atmosphere. I really appreciate that.”

The hardware stage enables us to adapt the masts to the requirements and needs of our customers. It is in this workshop that the carbon masts are fitted with hardware.

These include mainsail tracks, locks, steps, sheave boxes, as well as navigation and ambiance lights…

« « I became a halyard fitter at Lorima after specializing with a training certificate in nautical joinery. Fitting the last metal parts on the masts requires concentration and application. What do I like about this manual job? Seeing masts, booms and crossbeams being fitted in our workshops. There’s a good working atmosphere, which is very important to me on a daily basis”.

All rights reserved Lorima